The main objective of the work is to optimize the transesterification process for biodiesel production to yield biodiesel that has the best properties such as viscosity cetane number flash point fire point and calorific value. PRODUCTION OF BIODIESEL FROM VEGETABLE OIL BY TRANSESTERIFICATION PROCESS USING CONTINOUS ENZYMATIC REACTOR Advisors.

Evc1 Transesterification To Biodiesel

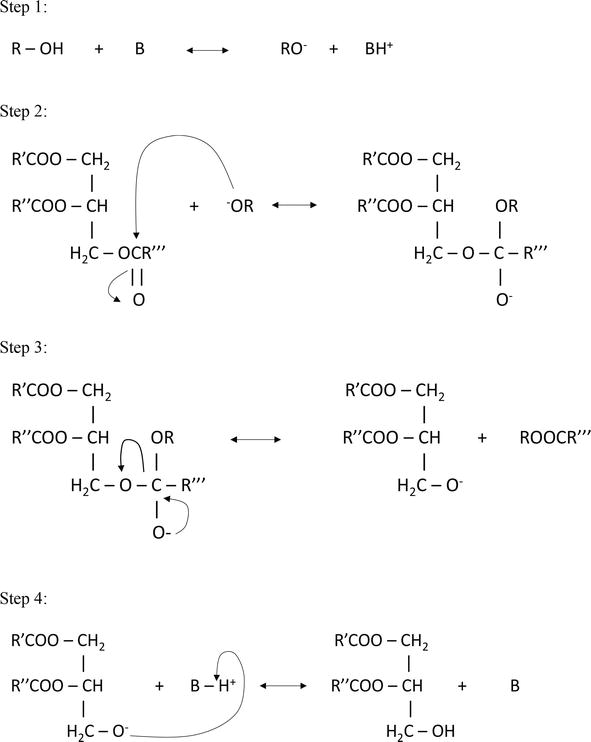

The use the enzyme lipase as a biocatalyst for the transesterification reaction step in biodiesel production has been extensively investigated.

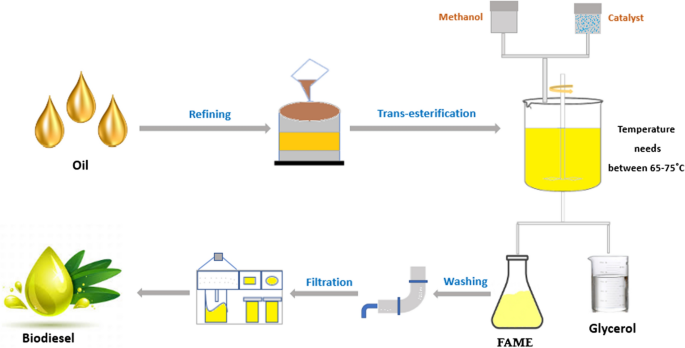

. 22 Flow Chart- Take Allow mixture to sit for about 24 hours 23 Calorific analysis-. After twenty-five years of study the description of the kinetics of transesterification for biodiesel remains controversial. Via transesterification process in the presence of catalyst.

Free easy returns on millions of items. Conventional diesel fuel was the base fuel for comparing the above. Free shipping on qualified orders.

In this study vegetable oil methanol and a homogenous alkaline catalyst 15 are studied. Of Mahua Mahua Bio-Diesel Bio Diesel Transesterification Process Figure 2 Table 2 Specifications of magnetic stirrer No. Batch Process Most common small-scale and home-brewing process Slow reaction times 1-8 hrs.

In-line Shear Reactors Large-scale Fast reaction times 1-2 hrs. Read customer reviews find best sellers. Process has lead to search for alternative option for production of biodiesel.

Jatropha oil nonedible vegetable oil was used to produce biodiesel. Biodiesel has emerged as a viable substitute for petroleum diesel. Methyl ethyl 2-propyl and butyl esters were prepared from vegetable oils through transesterification using potassium andor sodium alkoxides as catalysts.

Ad Browse discover thousands of brands. The purpose of the transesterification process is. The fuel can be made easily from either virgin or waste vegetable oil.

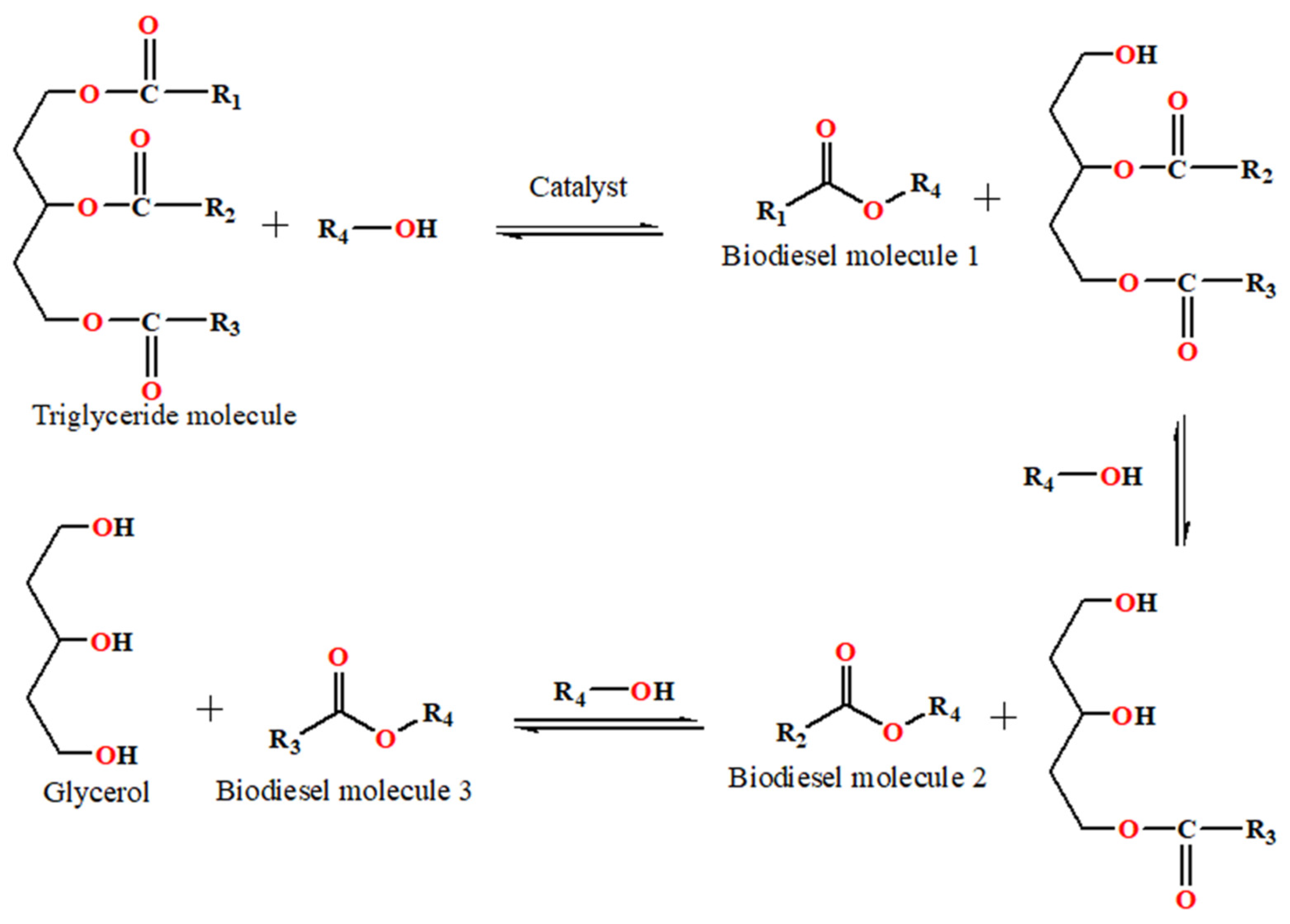

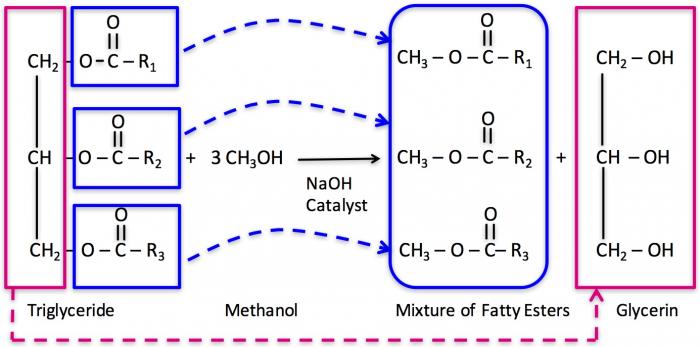

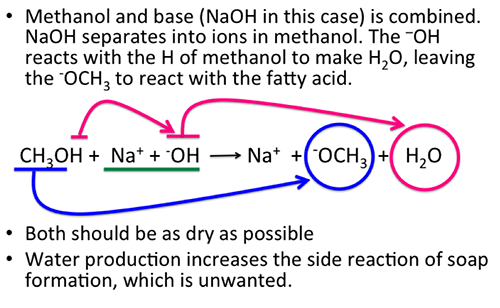

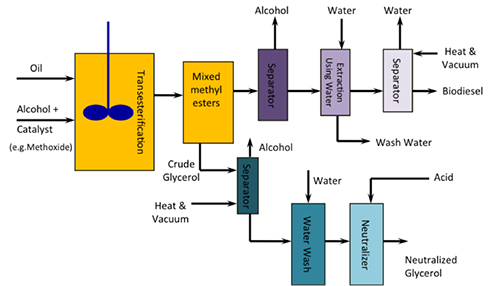

Transesterification process biodiesel is produced from a reaction between vegetable oil alcohol in the presence of base or acid catalyst. Biodiesel is produced 8-by the transesterification reaction between lipids animal fats or plants and short chain of alcohol methanol or ethanol in a base or acid catalyst. The purity of the produced biodiesel determined by gas chromatography was 95 at optimal conditions 05 NaOH 121 molar ratio for 2 hoursThe measured fuel properties of the produced biodiesel samples fell within the requirements of American Standard for biodiesel fuel suggesting the viability of the process and its scale up for mass.

Improvement of Biodiesel Production in Batch Transesterification Process. Process produces biodiesel and triacetin a known fuel additive which does not have to be removed from. Lipase is produced by all living organisms and can be used intracellularly or extracellularly.

And glycerol is used in pellet formation. Specifications ValuesRange 1 Maximum stirring volume 0-3000 0 ml 2 Stirring speed range 0. Methanol is most preferred alcohol because of its low cost and its physical and chemical properties.

Transesterification Biodiesel from mahua oil was prepa prepared red through Transesterification process with methanol and KOH. Ultrasonic Reactors Not widely practiced in current production Potential to dramatically reduce amount of catalyst used and reaction time requirement 15 min. A common means of production is base-catalyzed transesterification.

From which we get Biodiesel as product and glycerol as byproduct. This biodiesel is then tested for calorific value. The highest biodiesel yield was at 3 weight of catalyst 60 o C and reaction time of 120.

Enzyme Transesterification Process The Resulting Products Of This Download Scientific Diagram

Transesterification An Overview Sciencedirect Topics

Role Of Microbial Lipases In Transesterification Process For Biodiesel Production Springerlink

Transesterification Srs Biodieselsrs Biodiesel

Pdf Base Transesterification Process For Biodiesel Fuel Production From Spent Frying Oils

Catalysts Free Full Text Nanobiocatalysts For Biodiesel Synthesis Through Transesterification A Review Html

9 2 The Reaction Of Biodiesel Transesterification Engineering Libretexts

Pdf Biodiesel Production With Special Emphasis On Lipase Catalyzed Transesterification

Effects Of Process Variables On Transesterification Reaction Of Jatropha Curcas Seed Oil For The Production Of Biodiesel Semantic Scholar

Pdf Technical Aspects Of Biodiesel Production By Transesterification A Review

Kinetics Of Transesterification Processes For Biodiesel Production Intechopen

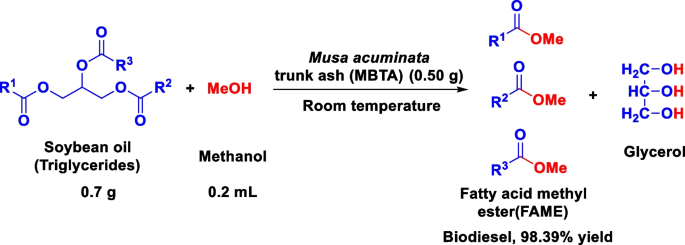

A Sustainable Protocol For Production Of Biodiesel By Transesterification Of Soybean Oil Using Banana Trunk Ash As A Heterogeneous Catalyst Springerlink

9 2 The Reaction Of Biodiesel Transesterification Engineering Libretexts

Widely Used Catalysts In Biodiesel Production A Review Rsc Advances Rsc Publishing Doi 10 1039 D0ra07931f

General Reaction Of Enzyme Catalyzed Transesterification Process B Download Scientific Diagram

Pdf Technical Aspects Of Biodiesel Production By Transesterification A Review

Transesterification An Overview Sciencedirect Topics

9 2 The Reaction Of Biodiesel Transesterification Engineering Libretexts

Transesterification An Overview Sciencedirect Topics